CDW Steel Tubes

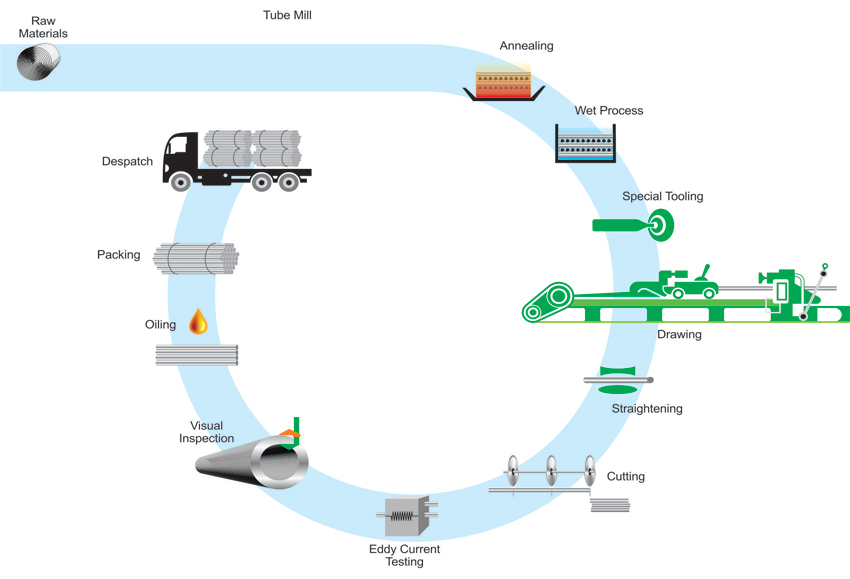

CDW tubes are customised products as required by customers for specific purposes wherein high precision, tolerance, tensile strength, mechanical enhancement, better surface finish, custom sizes and quantities etc are desired. Herein, the finished ERW tube is the starting raw material from which the CDW tubes are made. ERW tubes are subjected to processes like pickling, annealing, lubricating and swaging. Next, the desired size is attained by passing the tube through multiple drawing operations. A final round of visual and mechanical inspection is followed by oiling, packing and dispatch.

CDW TUBE PLANT – (Size Range : OD 8 mm to 70 mm & Thk 0.80mm to 4.00mm)

Along with Roller Hearth Furnace 1.5 Ton / hour capacity supplied by Allied Engg. – Mumbai.

ROLLER HEARTH FURNACE

DRAW BENCH

CDW Tube Division

| SI.NO | Particulars | Capacity | Qty.in.Nos |

|---|---|---|---|

| 1 | Roller Hearth Furnace | 1.5 MT / Hr | 1 |

| 2 | Draw Bench | 40 Ton Capacity | 3 |

| 3 | Nitrogen Gas Plant | 100 NM3 | 1 |

| 4 | Surface Treatment Plant | 1 | |

| 5 | Thermo Pack – Thermic Fluid Heater | 1 | |

| 6 | Swaging / Push Pointing Machine | 5 | |

| 7 | Cutting Machine | 1/2" to 2" | 2 |

| 8 | Straightening Machine - 1.6 Roll type | 8 mm to 30 mm OD | 1 |

| 9 | Straightening Machine - 2.10 Roll type | 30 mm OD and above | 1 |

| 10 | Eddy Current Tester Machine | 1 |

| SURESH STEEL TUBES PVT LTD | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PRODUCT RANGE FOR CDW TUBES | |||||||||||||||||||

| CDW | THICKNESS (mm) | ||||||||||||||||||

| OD(mm) | 0.80 | 0.90 | 1.00 | 1.25 | 1.50 | 1.60 | 1.80 | 2.00 | 2.30 | 2.60 | 2.80 | 3.00 | 3.25 | 3.60 | 4.00 | ||||

| 8.00 | |||||||||||||||||||

| 9.00 | |||||||||||||||||||

| 10.00 | |||||||||||||||||||

| 12.00 | |||||||||||||||||||

| 12.70 | |||||||||||||||||||

| 14.00 | |||||||||||||||||||

| 15.00 | |||||||||||||||||||

| 18.00 | |||||||||||||||||||

| 19.05 | |||||||||||||||||||

| 20.00 | |||||||||||||||||||

| 22.23 | |||||||||||||||||||

| 25.40 | |||||||||||||||||||

| 28.58 | |||||||||||||||||||

| 31.75 | |||||||||||||||||||

| 34.00 | |||||||||||||||||||

| 38.10 | |||||||||||||||||||

| 41.28 | |||||||||||||||||||

| 44.45 | |||||||||||||||||||

| 45.00 | |||||||||||||||||||

| 46.00 | |||||||||||||||||||

| 48.30 | |||||||||||||||||||

| 50.80 | |||||||||||||||||||

| 55.56 | |||||||||||||||||||

| 57.15 | |||||||||||||||||||

| 60.33 | |||||||||||||||||||

| 63.50 | |||||||||||||||||||

| 65.00 | |||||||||||||||||||

| 69.85 | |||||||||||||||||||

| 70.00 | |||||||||||||||||||